Views: 2 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

In the current era focused on green development and a sustainable future, the treatment of industrial wastewater and domestic sewage has become a focal point of societal concern. In this "battle for clean water," a piece of equipment called the Dissolved Air Flotation (DAF) unit is playing a central role, much like a "magician," efficiently and cleanly turning murky water clear and transforming filth into clarity.

1. What is a DAF Unit? – The "Art" of Separation

While the term "Dissolved Air Flotation Unit" might sound technical, its principle cleverly applies basic physics. Think of it as a highly efficient "impurity floater and separator."

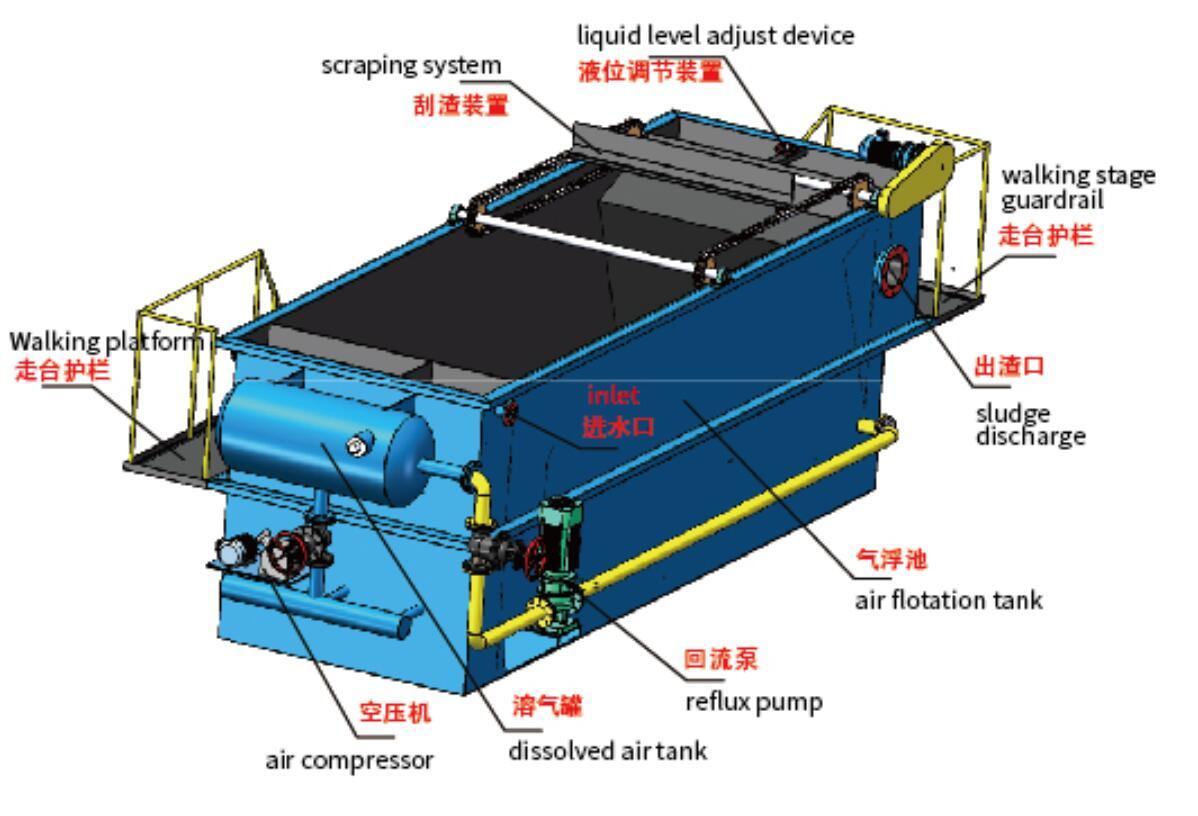

Its core working principle is this: through a dedicated air dissolution system, air is dissolved into water under high pressure, creating "air-saturated water." When this saturated water is released into the tank containing the wastewater to be treated, the pressure drops suddenly. The dissolved air instantly escapes, forming a vast number of extremely fine, dense micro-bubbles. These bubbles act like tiny "buoyancy grippers," quickly attaching to suspended solids, oils, fats, colloids, and other lightweight impurities in the water, forming "bubble-impurity" complexes. Because their overall density is less than that of water, these complexes rapidly float to the surface due to buoyancy, forming a distinct layer of scum or "float." Finally, a specialized skimmer mechanism removes this float layer, leaving the purified, clear water below.

This process of "turning waste into floating scum, leaving clear water beneath" is efficient and intuitive, truly an "art" of separation in the water treatment field.

2. Why is It Highly Favored? – Efficient, Energy-Saving, Wide Applications

Compared to traditional sedimentation methods, why has the DAF unit become the preferred choice for numerous wastewater treatment plants and industrial enterprises? Its advantages are mainly reflected in three areas:

1. High Treatment Efficiency, Remarkable Results: For lightweight particles with a specific gravity close to water (such as oils, fats, fibers, algae) that are difficult to remove by natural sedimentation, the flotation separation method is much faster than sedimentation and requires a smaller footprint. Its high surface loading rate and short hydraulic retention time enable rapid solid-liquid separation, producing clear, translucent effluent.

2. Low Operating Costs, Energy Efficient and Eco-Friendly: Modern DAF units feature intelligent designs with a high degree of automation, reducing manual operation costs. Furthermore, their core air dissolution systems are continuously optimized for effective energy consumption. By recycling treated clean water to create more air-saturated water, they also enable water recycling, aligning with energy-saving and environmental principles.

3.Wide Range of Applications, Strong Adaptability:Whether it's pulp recovery in the paper industry, oily wastewater from food processing plants, heavy metal ion removal in electroplating facilities, oil-containing wastewater treatment in petrochemical plants, or even algae removal in municipal water supply, DAF units prove highly effective. Their flexible process design allows them to adapt to various complex water quality conditions.

3. Innovation Drives the Future: The Evolution of DAF Technology

The lifeblood of technology is innovation, and DAF technology is no exception. To meet increasingly stringent environmental standards and diverse treatment needs, the technology is constantly evolving.

High-Efficiency Air Release Systems:New generations of air release systems can produce even finer, more uniform micro-bubbles, with diameters as small as microns, significantly increasing the contact area and adhesion efficiency between bubbles and pollutants.

Intelligent Control Systems: By integrating PLCs, sensors, and IoT technology, modern DAF units can achieve fully automatic operation. The system can automatically adjust air dissolution pressure, chemical dosing rates, and skimming frequency based on incoming water quality and flow, ensuring optimal performance and enabling "smart water treatment."

Combined Process Applications:A growing number of cases show that combining DAF units with processes like MBR (Membrane Bioreactors) and biological treatment creates a more powerful treatment synergy, tackling high-difficulty industrial wastewater and demonstrating a "1+1>2" effect.

Conclusion: The Unsung Hero Guarding Clear Waters and Green Mountains

The Dissolved Air Flotation unit, a critical step in the water treatment process, may not be as conspicuous as large biological tanks, but it works diligently and efficiently to protect our environment. From compliant wastewater at factory discharge points to clean water in municipal treatment plants, this "magician" works tirelessly behind the scenes. As the philosophy that "Lucid waters and lush mountains are invaluable assets" takes deep root, DAF technology—mature yet continually advancing—will undoubtedly continue to play an indispensable role in painting a beautiful picture of a harmonious coexistence between humans and nature.