Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

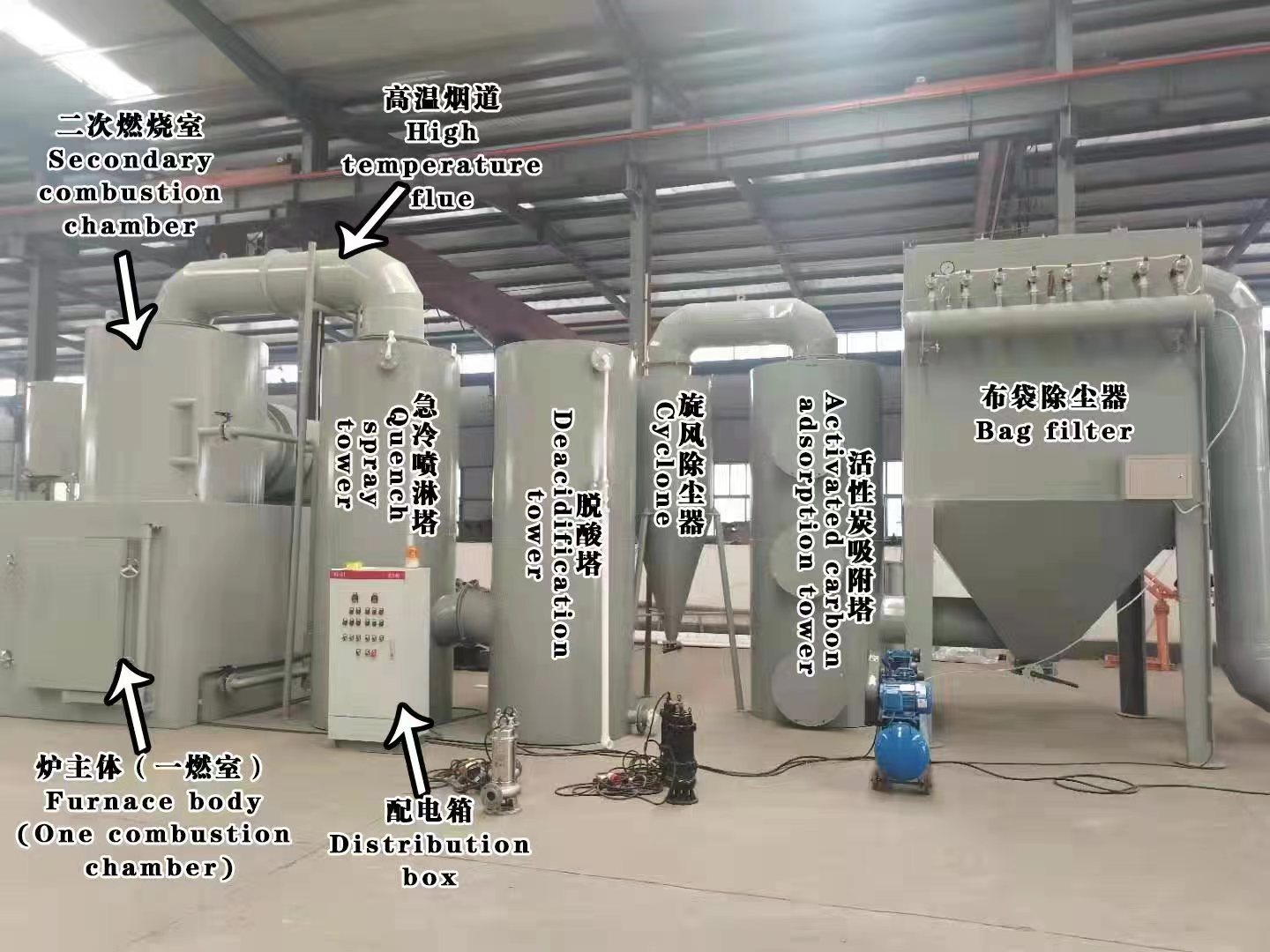

As environmental regulations become increasingly stringent, traditional incineration technologies can no longer meet the demands for dioxin control and acid gas purification. The introduction of spray technology, through the synergistic mechanism of "incineration + spray," has achieved breakthroughs in temperature regulation, pollutant removal, and resource recovery. This article will analyze the working principles, technical advantages, and future development of this technology from three dimensions.

I. Core Technical Principles

Precision Temperature Control System

The spray system injects atomized liquid (water or chemical solutions) into high-temperature flue gas zones via high-pressure nozzles. Utilizing the heat absorption principle of liquid vaporization, it can rapidly reduce flue gas temperature from 500°C to 200°C within 1 second, effectively inhibiting dioxin re-synthesis (critical temperature range: 250–400°C). For example, a medical waste treatment project achieved stable furnace temperature control within a ±5°C error range using multi-stage spraying.

Multi-Pollutant Synergistic Purification

Acid Gas Treatment: Filled with NaOH solution in the spray tower, removal rates for HCl and SO₂ exceed 95%.

Particulate Capture: Through the Venturi effect, the removal efficiency for particles above 10μm surpasses 90%.

Heavy Metal Interception: Chelating agents can solidify heavy metal ions like lead and cadmium.

II. Industrial Application Advantages

Optimized Operating Costs

Compared to traditional baghouse dust removal + RTO incineration combined processes, spray-type incinerators can reduce energy consumption by 20–30%. A paper mill' data showed annual natural gas savings of 150,000 cubic meters when treating the same load of exhaust gas.

Modular Scalability

The standardized design of "incineration unit + spray module" allows flexible adjustment of spray tower stages based on processing capacity. A solid waste treatment center in Shenzhen increased its capacity from 5 tons/day to 8 tons/day by adding three-stage spray units.

III. Technological Development Trends

Intelligent Control Systems

AI algorithms dynamically adjust spray parameters (e.g., pH, flow rate). A pilot project achieved an 18% reduction in chemical dosing while exceeding EU 2010 emission standards.

Innovative Resource Recovery

Recent studies show that spray wastewater can yield industrial raw materials like NaCl and CaSO₄ after evaporation and crystallization. Kawasaki Heavy Industries has built the first commercial recovery production line.

Conclusion

Spray technology has endowed incinerators with a new "environmentally friendly" attribute. Its integration with combined heat and power (CHP) and carbon capture technologies will drive the waste treatment industry toward "negative-carbon factories." Future efforts should focus on breakthroughs in corrosion-resistant materials for spray systems and atomization efficiency improvements