Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

As an efficient solid-liquid separation device, selecting the appropriate DAF unit directly impacts the operational performance, investment cost, and maintenance difficulty of a water treatment system. Faced with various types and brands of DAF equipment on the market, understanding the core selection factors is paramount.

1. Treatment Objectives: What pollutants are primarily targeted for removal (SS, oils/greases, algae, flocs)? What target removal efficiency is required? What are the effluent standards?

2. Water Quality & Quantity: Detailed raw water characteristics are crucial (SS concentration, oil/grease content, pH, temperature, wastewater type). Design flow rate (average flow, peak flow) is the core basis for equipment sizing.

3. Installation Conditions: Available site dimensions (L x W x H constraints), inlet/outlet pipe locations and elevations, power supply conditions (voltage, power requirements).

4. Downstream Processes: What treatment unit will the DAF effluent enter? How will the produced float sludge be handled? This influences requirements for DAF effluent quality and sludge concentration.

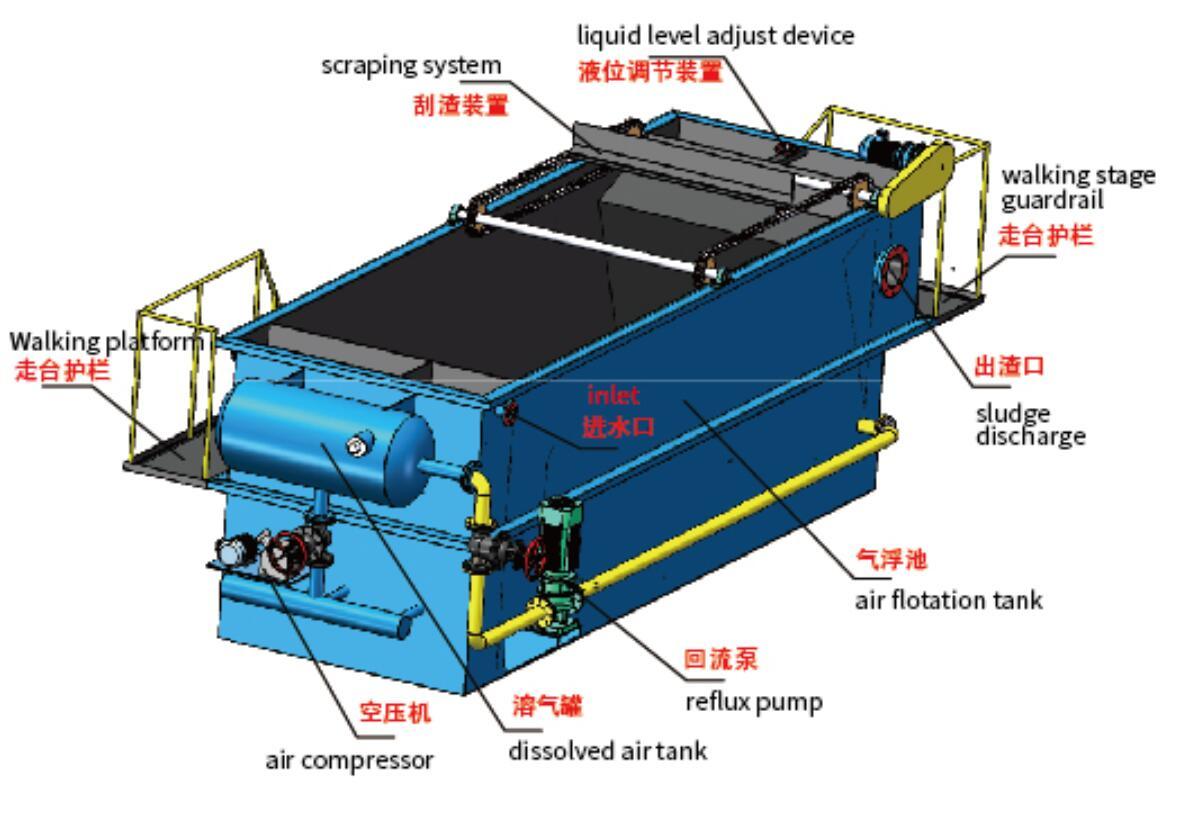

◦ Traditional Rectangular DAF: Technologically mature, simple and reliable structure, easy maintenance, good adaptability to flow and load variations. Most widely applied.

◦ Shallow Depth DAF / High-Efficiency Shallow DAF: Based on "Zero Velocity" or "Shallow Depth" theory. Flow in the separation zone approaches laminar, requiring much shorter retention times (only minutes) and significantly higher surface loading rates (up to several times traditional DAF), resulting in minimal footprint. Especially suitable for space-constrained sites or large treatment capacities. Requires slightly more stable influent quality.

◦ Cavitation Air Flotation (CAF) / Induced Air Flotation (IAF): Eliminates the need for a pressure tank and air compressor. Uses a mechanical rotor rotating at high speed to create a vacuum that draws in and shears air, generating bubbles. Lower energy consumption, relatively simple maintenance. Bubbles are larger; requires stronger flocs. Suitable for simpler water qualities and moderate treatment requirements.

2. Treatment Capacity (Size): The core metric is the design flow rate (m³/h). Suppliers typically calculate the required effective surface area or design equipment based on the hydraulic surface loading rate (m³/m²·h). It is imperative to account for peak flow conditions.

3. Material Considerations: Significantly impacts equipment lifespan and cost.

◦ Carbon Steel with Corrosion Protection (FRP-lined, Epoxy-coated, Enameled, etc.): Most common, cost-effective. Quality of coating/weld protection is critical.

◦ Stainless Steel (304/316): Excellent corrosion resistance, long lifespan, aesthetically pleasing. Ideal for high-standard industries like food, pharma, chemicals, and seawater applications. Higher cost.

◦ Fiberglass Reinforced Plastic (FRP): Overall good corrosion resistance, lightweight, requires no weld protection. Slightly lower impact resistance.

4. Air Dissolution System: The Soul of DAF.

◦ Dissolution Method: Common methods are Venturi (Jet) Dissolution (relatively lower energy, simpler maintenance) and Pressurization Pump + Air Compressor (more stable & efficient). High-efficiency saturators (e.g., packed columns for increased contact area) and precision microbubble release valves/nozzles (producing finer, more uniform bubbles) are key value-enhancing features.

◦ Saturation Efficiency (Dissolved Air Quantity): Directly determines bubble quality and flotation effectiveness. Focus on saturator design pressure and saturation efficiency (%).

5. Sludge Removal (Skimmer) System: Directly impacts sludge removal efficiency and operational continuity.

◦ Type: Chain-and-flight skimmer (most common, stable, reliable), Spiral skimmer (suitable for long channels), Rotating scrapers.

◦ Drive/Control: Motor power, variable speed functionality, auto/manual control, reliability of travel limit switches.

6. Ancillary Equipment:

◦ Chemical Feed Systems: Accurate dosing of PAC/PAM is critical for DAF performance. Needs determination based on water quality.

◦ Piping, Valves & Instrumentation (P&ID): Completeness and quality of monitoring points (pressure gauges, flow meters, level sensors).

◦ Electrical Control System: Level of automation (PLC/DCS control), remote monitoring capability, safety features (high/low-level switches, pressure protection, etc.).

7. Energy Consumption & Operating Costs:

◦ Major power consumers are the dissolution system (air compressor, recycle pump) and the skimmer drive.

◦ Efficient dissolution systems, optimal loading design, and variable frequency drives (VFDs) are key to energy savings.

◦ Chemical costs (coagulants/flocculants) must also be factored in.

Selecting a DAF unit is a comprehensive decision-making process combining scientific calculations (hydraulic loading, saturation efficiency, etc.) and engineering practical experience (water characteristics, operational management conditions). Clear understanding of your own needs is the critical starting point. A deep understanding of core parameter significance and impacts, comprehensive comparison of supplier proposals and quotes, and a focus on the equipment's long-term stability, efficiency, and operating costs will help you select the "right-fit" DAF unit for your project, ensuring the entire water treatment system runs efficiently, economically, and sustainably. During the selection process, pose custom "challenge scenarios" (e.g., unusual water characteristics, space constraints) to test a supplier's technical flexibility and problem-solving capability.